![[field:title/]](/uploads/1804/1-1P4101401461H.jpg)

| �ͷ��ᾀ��0512-80606568 |

|

English |

| �ͷ��ᾀ��0512-80606568 |

|

English |

�ʽ����C

![[field:title/]](/uploads/1804/1-1P4101401461H.jpg)

|

���|(zh��)���Ϳɿ��� ���缉�Ĺ�ˇ�Ͳ��� ģ�Kʽ,���o���ӽY(ji��)��(g��u) ��ͬ���e����C���S�и����Ă��S��Ҏ(gu��)����ͬ �T䓄���w��ǰ���w ���w�T��S���� ���ޏ�(f��)������C�C�� ���܃�(y��u)�� ǡ����̎������ǻ�O(sh��)Ӌ ��_��,���߹��� С���Ͽ��O(sh��)Ӌ ��N�X���߅�o���m�ø��N��(y��ng)�� |

ʹ�úͰ��b�ɱ��� ���ڌ��F(xi��n)�Ԅӻ� ���ٶ���ȫ���p囉K���Ͽ��{(di��o)��ϵ�y(t��ng) ���o�尲�b������ ���z�K���b һ�w���ęC늵��� �w݆���o�ֽY(ji��)��(g��u)�o��,�����ھS�� ���ƵĽo�ϲ� �Ԅ���֬���� ��(y��ng)�ÏV���Ĺ̶����Ƅ��O(sh��)�� ʯ�� �Vɽ(���Ϻ;���) �U�����(���������r���) ���I(y��)(�V����ꖘO��) |

|

High quality and reliability word-class craftsmanship and material Modular,non welded construction Four equal size bearings that larger than those of most crusher of comparable size Cast steel pitman and crusher frames Single-piece cast steel frame bearing housings Repair crusher construction Outstanding performance Efficient cavity designs Long stroke,optimum speed Small allowed crusher settings The Right jaws and cheek plates for the widest range of applications |

Low operating and installation costs Easy to automate Fast and safe wedge setting adjustments system Protection plates behind the jaw plates Rmper crusher mounting Versatile integral motor base Compact and service friendly flywheel guards Custom feed chute Automatic grease lubrication system Used in a wide range of applications,both stationary and mobile Aggregate Minling(surface and underground) Recycling(concrete,asphalt,etc) Industrial(slag,anodes,etc) |

| ���g(sh��)��(sh��)��(j��) |

|

����CҎ(gu��)�� Model |

MC800 | MC1000 | MC1060 | MC1080 | MC1100 | MC1200 | MC1250 | MC1300 | MC1500 | MC1600 | MC2000 |

| �o�Ͽڌ��ȣ�mm��Feed opening width | 800 | 1000 | 1060 | 1200 | 1100 | 1200 | 1250 | 1300 | 1400 | 1600 | 2000 |

| �o�Ͽ����***����mm��Feed opening depth | 510 | 760 | 700 | 830 | 850 | 870 | 950 | 1070 | 1200 | 1200 | 1500 |

| ���ʣ�Kw��Power | 75 | 110 | 110 | 132 | 160 | 160 | 160 | 160 | 200 | 250 | 400 |

| �D(zhu��n)�٣�rpm��speed | 350 | 260 | 280 | 260 | 230 | 220 | 220 | 220 | 220 | 200 | |

| ����C����*kg | 7670 | 20060 | 14350 | 27600 | 25800 | 26200 | 41800 | 41500 | 51200 | 76500 | 121510 |

| ���a(ch��n)����(t/h)Capicity | 55-330 | 120-485 | 155-505 | 165-795 | 165-550 | 170-545 | 240-750 | 330-965 | 420-950 | 435-1150 | 630-1440 |

|

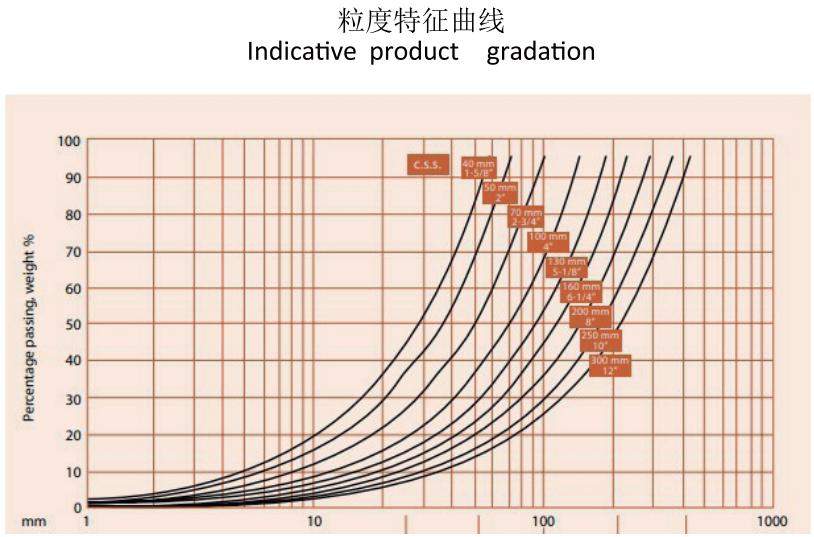

�a(ch��n)Ʒ�ߴ磨mm�� Product size |

�o߅���Ͽڣ�mm) Closed side Setting |

MC800 | MC1000 | MC960 | MC1060 | MC1160 | MC1100 | MC1200 | MC1250 | MC1400 | MC1600 | MC2000 |

| �a(ch��n)��Mtph����/�r�� | ||||||||||||

| 0-60 | 40 | 55-75 | �� | �� | �� | �� | �� | �� | �� | �� | �� | �� |

| 0-75 | 50 | 80 - 90 | �� | �� | �� | �� | �� | �� | �� | �� | �� | �� |

| 0-90 | 60 | 85 - 120 | �� | 115 - 150 | �� | �� | �� | �� | �� | �� | �� | �� |

| 0-105 | 70 | 110 - 145 | 145-205 | 135 - 175 | 155 - 195 | 160 - 215 | 230 -300 | 185-245 | �� | �� | �� | �� |

| 0-120 | 80 | 125 - 165 | 165 - 220 | 155 - 205 | 170 - 225 | 180 - 245 | 265 -345 | 205-270 | �� | �� | �� | �� |

| 0-135 | 90 | 145 - 190 | 180 - 240 | 175 - 230 | 195 - 255 | 210 - 270 | 290 - 380 | 230-300 | �� | �� | �� | �� |

| 0-150 | 100 | 160 - 210 | 210 - 275 | 195 - 255 | 215 - 280 | 230- 300 | 320- 420 | 350-325 | 280- 375 | �� | �� | �� |

| 0-185 | 125 | 205 - 270 | 260 - 340 | 245 - 320 | 270 - 360 | 290 - 380 | 385- 505 | 305-400 | 450 - 585 | 380- 495 | �� | �� |

| 0-225 | 150 | 245 - 320 | 310 - 400 | 299 - 385 | 330 - 430 | 345 - 450 | 455- 595 | 360-470 | 400 - 530 | 450 - 580 | 510 - 670 | �� |

| 0-260 | 175 | 285 - 375 | 365 - 475 | 345- 450 | 385 - 505 | 400 -520 | 525- 685 | 420--545 | 460 - 600 | 510- 670 | 590 - 770 | 755 -985 |

| 0-300 | 200 | �� | 415-540 | �� | 440 - 575 | 450 - 595 | 595-775 | 475-620 | 520- 680 | 580 - 760 | 670-870 | 850 - 1100 |

| 0-340 | 225 | �� | �� | �� | �� | �� | �� | �� | 580- 765 | 650 - 845 | 740-970 | 940 - 1220 |

| 0-375 | 250 | �� | �� | �� | �� | �� | �� | �� | 640 -840 | 720 - 940 | 820-1060 | 1030 - 1340 |

| 0-410 | 275 | �� | �� | �� | �� | �� | �� | �� | �� | �� | 895-1160 | 1125 - 1460 |

| 0-450 | 300 | �� | �� | �� | �� | �� | �� | �� | �� | �� | 970-1270 | 1220- 1580 |

ע��ԓ��(sh��)��(j��)����(j��)��?sh��)�ʹ����r�ɼ��@��,��

����(j��)��;�����a(ch��n)Ҫ��,��ͨ�����Բ���С�ľo߅���Ͽ����a(ch��n),�����˽�����C�ھ��w��(y��ng)���е�����,��Ո�c���V���̎�(li��n)ϵ��

���ϔ�(sh��)��(j��)����ʾ������C�a(ch��n)��,����ᘌ�ƽ�����؞�2.7t/M3,���o ���܉�����M������ǻ���o�ܘ¬F(xi��n)��,���o����С���ŵV�ڼ��ϕrȡСֵ,����������ȡ��ֵ���a(ch��n)�������S�o�Ϸ�ʽ���������|(zh��)�T�����ȽM��,����ˮ����,����ɢ�ܶȺͿ����Զ�׃����

����C�o߅���Ͽڵęz�y��ʽ�S������X�͵�׃��������ͬ,������������C�������ͮa(ch��n)Ʒ���Ȯa(ch��n)��Ӱ�,���������ؿ��������C�����������ܣ�

1.�m��?sh��)���x��

2.�m��?sh��)Ľo�ϘO��

3.�ɿصĽo����

4.���Ľo�ϙC�����ͽo�ό���

5.��ֵ�����C���υ^(q��)

6.����Ƥ���C�c����C���������ƥ��

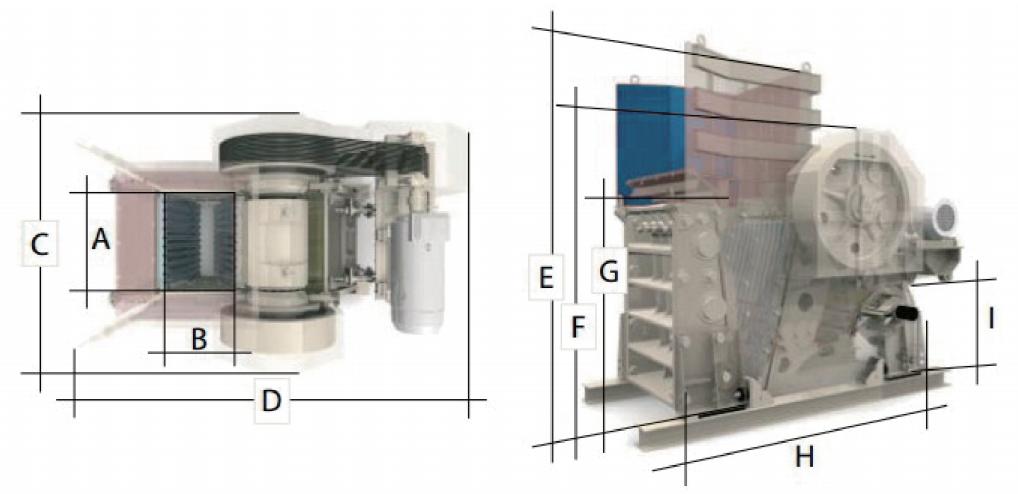

| �� | �� | MC80 | MC96 | MC100 | MC110 | MC125 | MC140 | MC145 | MC160 | MC200 |

| A | mm | 800 | 930 | 1000 | 1100 | 1250 | 1400 | 1400 | 1600 | 2000 |

| B | mm | 510 | 580 | 760 | 850 | 950 | 1070 | 1100 | 1200 | 1500 |

| C | mm | 1526 | 1755 | 2420 | 2385 | 2800 | 3010 | 3110 | 3700 | 4040 |

| D | mm | 2577 | 2880 | 3670 | 3770 | 4100 | 4400 | 4600 | 5900 | 6700 |

| D | mm | 1990 | 1610 | 2890 | 2890 | 3440 | 3950 | 4100 | 4580 | 4950 |

| F | mm | 1750 | 1460 | 2490 | 2750 | 2980 | 3140 | 3410 | 3750 | 4465 |

| G | mm | 1200 | 755 | 1700 | 1940 | 2100 | 2260 | 2430 | 2650 | 2800 |

| H | mm | 2100 | 2500 | 2965 | 2820 | 3470 | 3755 | 2855 | 4280 | 4870 |

| I | mm | 625 | 465 | 775 | 580 | 980 | 1050 | 1050 | 1300 | 1400 |

|

����C���� Basic crusher weight |

Kg | 7670 | 9759 | 20060 | 25800 | 37970 | 47120 | 54540 | 7130 | 121510 |

|

����C���� Total weight |

Kg | 9520 | 11870 | 23300 | 29500 | 43910 | 54010 | 63190 | 83300 | 137160 |